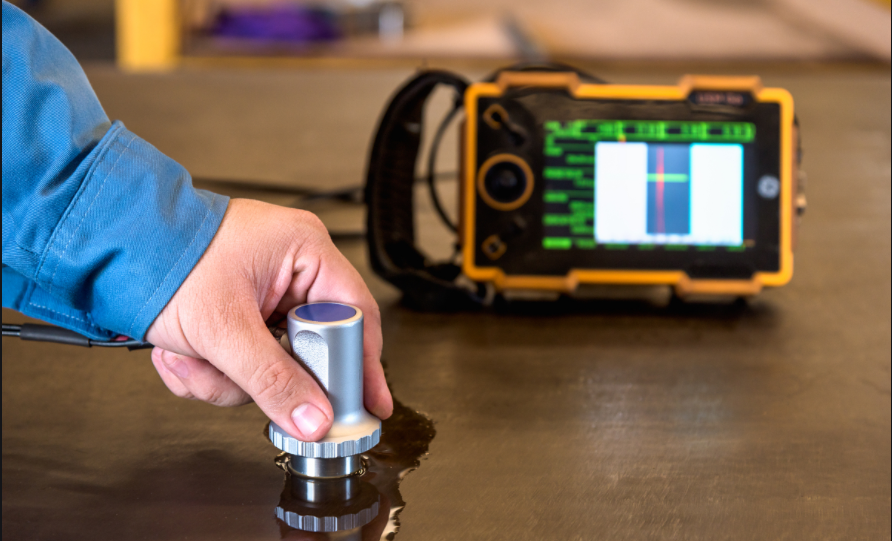

The company is equipped with ultrasonic nondestructive testing equipment, CMM and conventional testing equipment.

These can conduct nondestructive testing and full size inspection on key parts of FSW products to ensure product quality stability.

Ultrasonic nondestructive testing. We have nondestructive testing on FSW products, and eliminate pores, loose and other unqualified products.

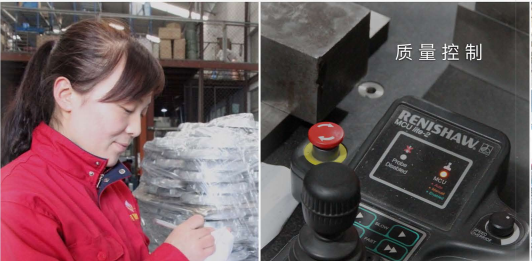

Three system controls the quality management of the production process to ensure the safety and control of the whole production process.

We uphold the quality first concept and are strict with quality inspection to provide customers with satisfactory friction stir welding products.