Cheeven provides water-cooled motor housing of high quality. Water cooling is a highly effective way to remove heat from the motor, and it maintains its cooling efficiency even at lower speeds, which makes it suitable for constant torque applications. Although combining water and electricity may appear risky, it offers clear advantages over current models.

With water cooling jacket for electric motor, it's possible to improve the power production capacity of a permanent magnet motor, making it smaller in size while still producing the same amount of power. Additionally, a motor with water cooling jacket is completely safe to use. For the maintenance methods, here are the methods you can click: water jacket electric motor.

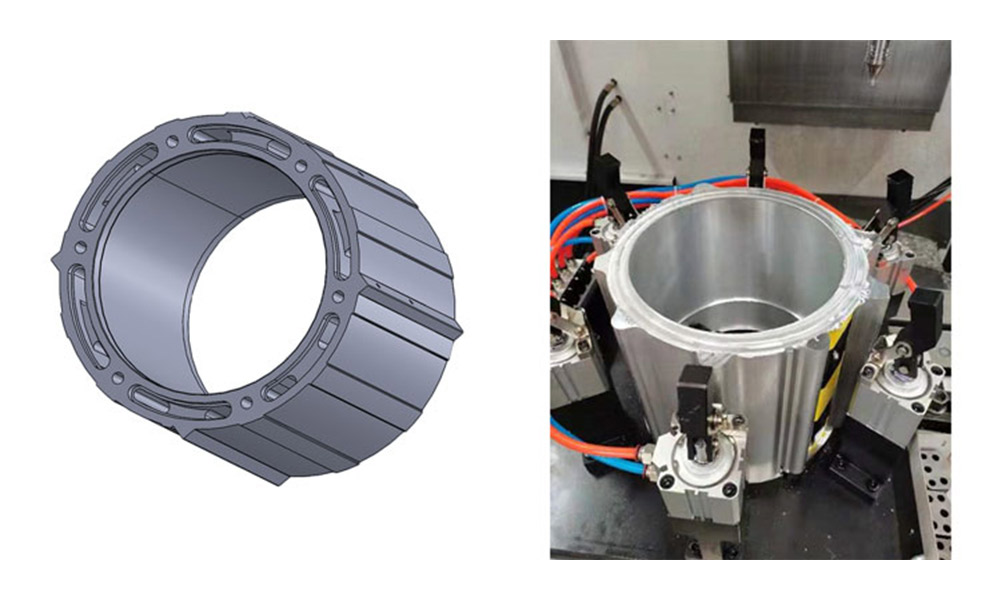

Because of the non-melting, automation, intelligence, environment-friendly and integrated characteristics, FSW friction stir welding has been widely used in the manufacturing and assembly of electric motor water jacket.

A water-cooling jacket is a type of cooling system used in various applications, such as in internal combustion engines and industrial equipment. Here are some advantages of using a water-cooled jacket:

High Efficiency: | Water has a high heat capacity, which means it can absorb a significant amount of heat energy without undergoing a significant temperature change. As a result, water-cooled jackets can efficiently remove heat generated by the engine or equipment, allowing it to operate at optimal temperatures. |

Consistent Temperature: | Water-cooling jackets provide a consistent temperature throughout the system, which is important for maintaining engine or equipment performance and preventing overheating. |

Reduced Noise: | Water-cooling jackets produce less noise compared to other cooling methods, such as air cooling, because the water acts as a buffer to absorb the sound. |

Longer Lifespan: | Water-cooling jacket for electric motor can help extend the lifespan of the engine or equipment, as they can prevent overheating and reduce wear and tear on the components. |

Environmentally Friendly: | Water is a natural and renewable resource, and using a water-cooled jacket can be a more environmentally friendly option compared to other cooling methods that rely on non-renewable resources or produce harmful emissions. |

The electric motor water jacket is a component of the engine that surrounds the cylinders and helps to cool the engine by circulating a liquid coolant around the engine block. Here are some common applications of cooling jacket engines:

Internal Combustion Engines: One of the most common applications of water-cooling jacket for electric motor is in internal combustion engines, including automotive engines, marine engines, and industrial engines. The water-cooled jacket helps to regulate the temperature of the engine by removing heat generated during combustion.

Industrial Equipment: Motor-cooling jackets are also used in a variety of industrial equipment, including generators, pumps, and compressors. By regulating the temperature of the equipment, the coolant jacket can help prevent overheating and improve the overall efficiency of the equipment.

Power Generation: In addition to industrial equipment, engine-coolant jackets are also used in power generation applications, such as in power plants and co-generation systems. The coolant jacket helps to remove heat generated during power generation and maintain the temperature of the engine or equipment.

Heavy Equipment: Electric motor cooling jacket are also used in heavy equipment, such as construction equipment and mining equipment. These applications often require high-performance engines that generate a significant amount of heat, making the motor water jacket an essential component for maintaining the proper operating temperature.

Racing Applications: In racing applications, water jacket electric motors are used to regulate the temperature of high-performance engines, such as those used in race cars and motorcycles. Maintaining the proper operating temperature is essential for ensuring optimal engine performance and preventing engine damage.

Product name | Motor housing/casing with cooling channel | ||

Type | Other Auto Parts | Shape | As Customer Requirements |

Material | Aluminum alloy | Condition | New |

Size | Customized | Warranty(Year) | 1 |

Applicable industry | Electric vehicle | Service | OEM/ ODM |

Marketing type | New Product | Place of Origin | Zhejiang, China |

Core components | Other | Processing | Extrusion, FSW, Machining |

MOQ(pieces) | 10 PCS | Certification | ISO9001: 2015 standard |

Product keywords: Friction Stir Welding, FWS products, Extruded Aluminum Alloy, Motor Housing, Motor Casing | |||

Cheever offers all types of friction stir welding products to meet your requirements.

A water cooling jacket system is a type of cooling system that uses water as a coolant to transfer heat away from a device or a machine. The water absorbs heat from the device and carries it away, dissipating it into the air through a radiator or other cooling mechanism.

While water cooling jacket for electric motor can offer many benefits, such as improved cooling efficiency and lower noise levels compared to air cooling, they do have some disadvantages. One major disadvantage of water cooling jacket is the risk of leakage. Water leaks can cause damage to the components of the device being cooled, leading to malfunction or even permanent damage.

Water cooling jacket can offer better cooling performance compared to air cooling systems, but it depends on the specific application and usage scenario.

Liquid cooling systems can transfer heat more efficiently than air cooling systems, thanks to the high specific heat capacity of water. This means that water can absorb more heat per unit of volume than air. As a result, liquid cooling systems can keep devices cooler than air cooling systems, which can lead to improved performance and longevity of the device.

Water-cooled jackets offer several advantages over air-cooled engines, including:

Improved Cooling Performance: One of the primary advantages of water cooled jackets is that they can dissipate heat more efficiently than air-cooled engines. The liquid engine coolant jacket can absorb more heat and transfer it away from the engine more effectively, which allows the engine to run at a more consistent and optimal temperature. This can result in improved engine efficiency, reduced wear and tear, and longer engine life.

Better Performance at High Temperatures: Water-cooled motor housing can maintain their performance even in hot environments or when subjected to high loads for extended periods of time. Air-cooled engines, on the other hand, can struggle to maintain their performance in high-temperature environments, which can lead to engine damage and reduced efficiency.

Quieter Operation: Water jacket electric motor can be quieter than air-cooled engines due to the use of a water jacket that surrounds the engine block, muffling noise and reducing vibration. This can make for a more pleasant driving experience, particularly in vehicles with larger, higher-performance engines.

Yes, air-cooled engines generally run hotter than water jacket electric motors. This is because air-cooled engines rely on airflow over the engine fins to dissipate heat, while water jacket electric motors use a circulating coolant to transfer heat away from the engine.