Aluminium alloy battery tray/lower box of battery pack is mainly made of steel and aluminium alloy. Aluminium alloy is favored by more and more automobile OEMs and battery tray manufacturers around the world because of low destiny of battery tray bracket and various forming processes, which can meet the requirements of electric vehicle lightweight.

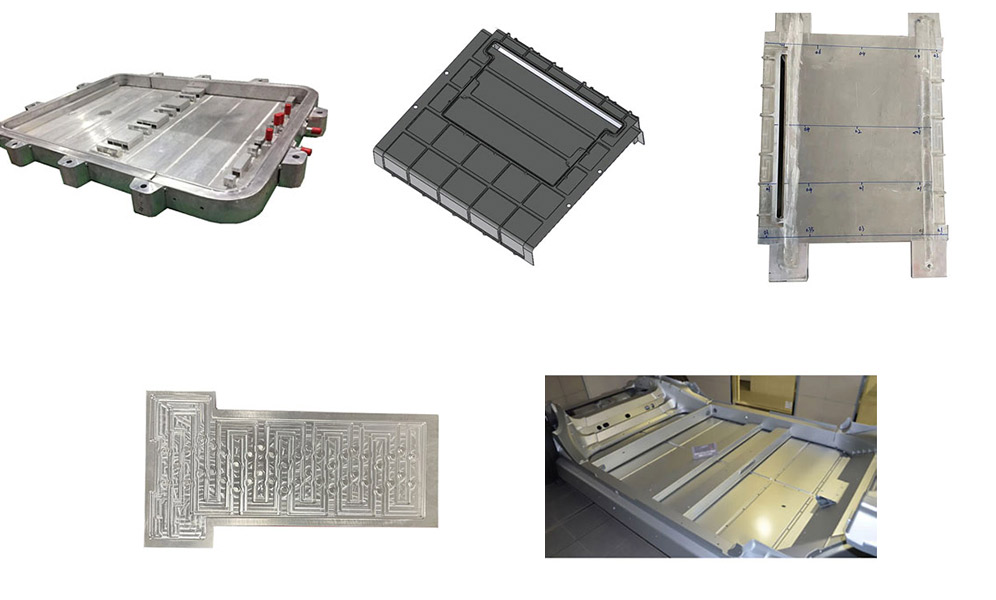

At present, the aluminium alloy battery tray has two process schemes for battery tray manufacturers: integral casting and aluminium profile welding. Friction stir welding has been widely used in universal battery tray manufacturing because of its non-melting, automation, intelligence, environment-friendly and integrated characteristics.

As one of the friction stir welding companies, Cheeven provides quality custom battery trays and battery tray kit wholesale at great market prices.

A universal metal battery tray design would be a standardized and interchangeable battery tray that can fit various sizes and types of batteries. Here are some factors to consider when designing a universal metal battery tray:

Size: The universal battery tray should be designed to accommodate various sizes of batteries, from small button cells to larger automotive batteries. The dimensions of the universal battery tray metal should be adjustable to fit different battery sizes.

Material: The universal metal battery tray should be made of a sturdy and durable material, such as steel or aluminum, that can withstand the weight of the batteries and any external forces.

Compatibility: The universal metal battery tray should be designed to be compatible with different types of batteries, such as alkaline, lithium-ion, and lead-acid batteries.

Mounting options: The universal EV battery tray FSW should have multiple mounting options, such as screw holes or brackets, to allow for flexible installation in different applications.

Safety features: For battery tray manufacturers, the universal metal battery tray should be designed with safety features, such as insulation or grounding, to prevent accidental short-circuits and damage to the batteries.

Ventilation: The hanging battery tray should allow for ventilation to prevent overheating of the batteries and reduce the risk of fire or explosion.

Accessibility: The battery tray for wheel arch should be designed to allow easy access to the batteries for maintenance or replacement.

Overall, a universal metal battery tray design should be flexible, durable, safe, and easy to use in different applications.

EV Battery Tray: An EV battery tray is specifically designed to hold the battery pack in electric vehicles. The EV battery tray FSW is often made of lightweight and sturdy materials like aluminum or composite materials, as it needs to support the weight of the battery pack. As one kind of FSW products, EV battery tray FSW is typically designed to be mounted in a specific location within the vehicle's chassis.

Auxiliary Battery Tray: An auxiliary battery tray is designed to hold an additional battery that powers non-essential electrical components in a vehicle, such as a stereo system or winch. These auxiliary battery trays can be mounted in various locations, depending on the specific vehicle and the desired electrical setup.

Double Battery Tray: A double battery tray ( twin battery tray) is designed to hold two batteries in a single tray. These dual battery holders are often used in vehicles that require a lot of electrical power, such as RVs or boats. The dual battery holder trays are typically mounted in a location that provides easy access for maintenance and monitoring.

Triple Battery Tray: A triple battery tray is similar to a double battery tray, but is designed to hold three batteries in a single tray. These triple battery trays are often used in vehicles that require even more electrical power than those that use double battery trays.

Hanging Battery Tray: A hanging battery tray is designed to be suspended from a vehicle's chassis or frame. These hanging battery trays are often used in vehicles where space is at a premium, as they can be mounted in locations that might not be accessible with other types of trays.

Under Tray Battery Tray: An under tray battery holder is designed to be mounted underneath a vehicle's chassis. These under tray dual battery boxes are often used in off-road vehicles, as they can provide protection for the battery while still allowing it to be easily accessible for maintenance.

Side Mount Battery Tray: A side mount battery tray is designed to be mounted on the side of a vehicle's chassis. These side mount battery trays are often used in vehicles that have limited space for a battery, or in situations where the battery needs to be mounted in a specific location to balance the weight of the vehicle.

Small battery tray for wheel arch: Typically used for small, compact batteries such as those used in motorcycles, ATVs, or lawn tractors. The size may range from around 6 inches long by 4 inches wide to 8 inches long by 6 inches wide, depending on the specific application.

Slim EV battery tray: These slim battery trays are designed to hold batteries that are longer and thinner than standard batteries, such as those used in some sports cars or high-performance vehicles. The size may range from around 11 inches long by 6 inches wide to 13 inches long by 8 inches wide, depending on the specific battery and vehicle.

Large alloy battery tray: Used for larger batteries, such as those used in boats, RVs, or heavy-duty equipment. The size may range from around 14 inches long by 8 inches wide to 20 inches long by 12 inches wide, depending on the specific battery and application.

Extra large EV battery tray: These extra large battery trays are the largest battery trays and are typically used for batteries that are even larger than those used in boats or RVs. The size may range from around 24 inches long by 14 inches wide to 36 inches long by 20 inches wide, depending on the specific application.

These battery trays for wheel arch are just rough estimates and actual sizes may vary depending on the specific manufacturer and product.

A Universal Metal Battery Tray can have a wide range of applications, including:

Battery Tray for Trunk: A alloy battery tray designed for use in the trunk of a car, providing a secure and stable location for the battery while also protecting the vehicle from acid leaks and other potential damage.

Battery Tray for Wheel Arch: A EV battery tray FSW that is mounted in the wheel arch of a vehicle, offering a space-saving and secure location for the battery that is also easily accessible.

Battery Tray RV: A battery tray for wheel arch designed for use in recreational vehicles (RVs), providing a secure and stable location for the battery while also protecting it from the elements and other potential damage.

Boat Lift Battery Tray: A EV battery tray designed specifically for use in boat lifts, providing a sturdy and durable location for the battery that is also resistant to corrosion and other environmental factors.

Camper Battery Tray: A hanging battery tray designed for use in campers and other mobile homes, offering a secure and stable location for the battery while also protecting it from the vibrations and jolts of the road.

Motorhome Battery Tray: A universal metal battery tray designed for use in motorhomes, providing a stable and secure location for the battery that is also resistant to the various environmental factors that motorhomes can encounter on the road.

Off Road Battery Tray: A alloy battery tray designed for use in off-road vehicles, offering a rugged and durable location for the battery that can withstand the bumps, jolts, and vibrations of extreme terrain.

Racing Battery Tray: A slim battery tray designed for use in high-performance racing vehicles, providing a lightweight and secure location for the battery that is also resistant to the extreme conditions that can be encountered on the track.

Product name | FSW aluminium alloy battery tray | ||

Type | Other auto parts | Shape | As customer requirements |

Material | Aluminium alloy | Condition | New |

Size | Customized | Warranty(Year) | 1 |

Applicable industry | Electric vehicle | Service | OEM/ ODM |

Marketing type | New product | Place of origin | Zhejiang, China |

Core components | Other | Processing | Extrusion, FSW, TIG, MIG, Machining |

MOQ(pieces) | 10 PCS | Certification | ISO9001: 2015 standard |

Product keywords: Friction stir welding suppliers, FSW, Aluminum alloy, Battery tray, custom battery trays, battery tray holder | |||

Cheever offers all types of friction stir welding products to meet your requirements.