Friction stir welding is an advanced and relatively mature welding technology. Friction stir welding is widely used in aviation, aerospace, ships, trains, automobiles, electronics, electric power and other industrial fields, creating considerable social and economic benefits, and providing a perfect technical solution for aluminium, magnesium, copper, titanium, steel and other metal materials.

It provides users with different types and uses of industrial FSW products processing, including: aerospace cylinder structural parts, aviation thin-walled structural parts, ships' wide band ribbed plates, high-speed trains' body structures, large thickness radar panels, automobile wheels, container profile wall plates, various structural radiators and heat sinkers, etc.

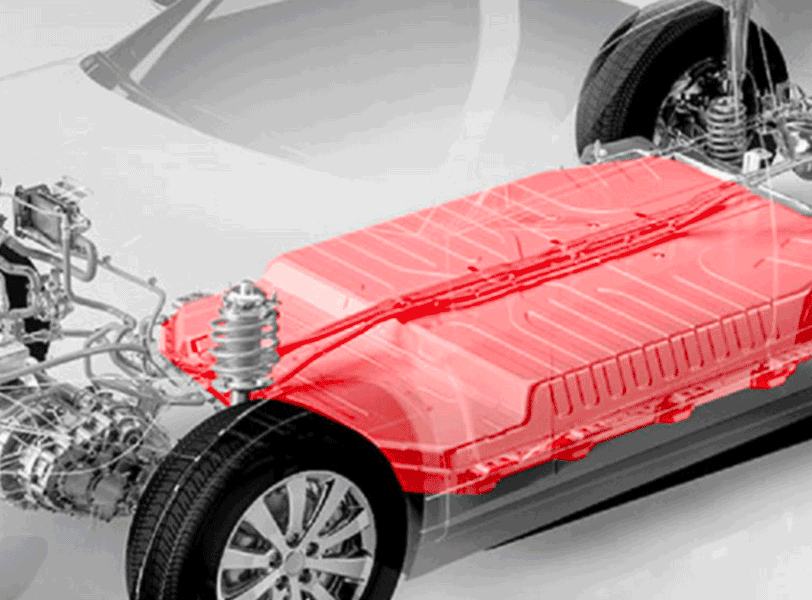

High-speed, energy-efficient and lightweight modern transport vehicles are the main trend in today's technological development. Lightweight land and sea transport vehicles, such as aluminium high-speed trains, all-aluminium cars and aluminium high-speed boats, are gaining in popularity. Friction stir welding technology has contributed to the rapid development of lightweighting. At the same time, light alloy materials such as magnesium and titanium alloys have been widely used and developed in the field of aircraft, missiles, launch vehicles and other aerospace vehicles. After more than ten years of research and practice, China Stir Friction Welding Equipment Centre has successfully realised the demand for lightweighting of automotive battery trays and automotive wheels. It has also made outstanding contributions to the lightweighting process in aerospace and rail transportation. Promoting the lightweighting of modern transport vehicles.

In the future, there is a trend towards lighter weight for stir friction welding applications in automotive manufacturing, modern transport and other applications. Light alloys such as aluminium, nickel and zinc are expected to replace steel as the main material for modern transportation such as automobiles. This friction stir welding technique differs from conventional welding techniques based on ferrous metals such as iron and manganese. It is ideally suited for welding light alloys such as zinc and aluminium, as well as for welding identical and different metals between these light alloys. It has outstanding advantages in the processing of light alloy materials. FSW products are used in the aviation, aerospace, shipbuilding, rail transportation and automotive industries and have a broad application prospect.

Friction stir welding is a solid phase welding method, before welding and during the welding process the environment pollution is small. The workpiece does not require strict surface cleaning preparation before welding, and the friction and stirring during the welding process can remove the oxide film on the surface of the welded parts, and there is no fume and spatter during the welding process, while the noise is low. Friction stir welding services are more energy-efficient than fusion welding or even conventional friction welding, as the welding head simply rotates and moves to achieve the entire weld seam step by step.

Cheeven, as top of friction stir welding suppliers, providing high-quality products like electric motor water jacket, alloy battery tray, battery cold plate and water cooling plate China.